Quick Stock

Quick delivery on powder-coated wire mesh decks

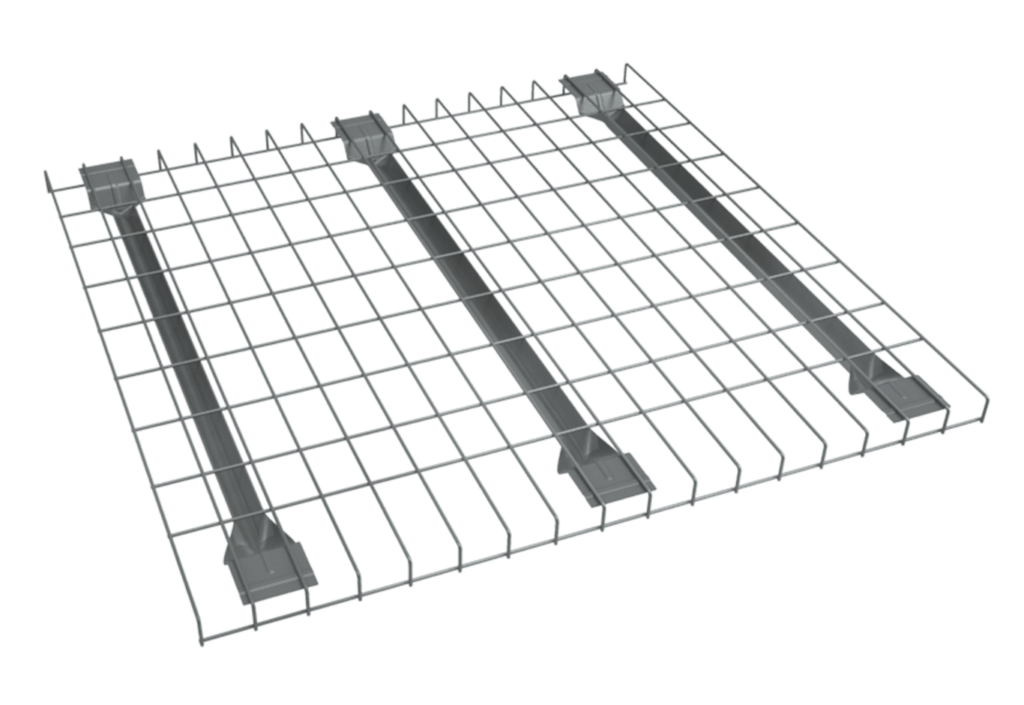

easySHELF™ Quick Stock powder-coated wire mesh decks comprise the most common sizes of wire mesh decking in the market based on standard pallet racking. This powder-coated solution is perfect for traditional projects or for getting replacements for damaged decks.

The Biggest benefit of the quick stock powder-coated wire mesh decks is we have a much larger stock holding and can therefore deliver larger projects on a short lead time at a lower cost.

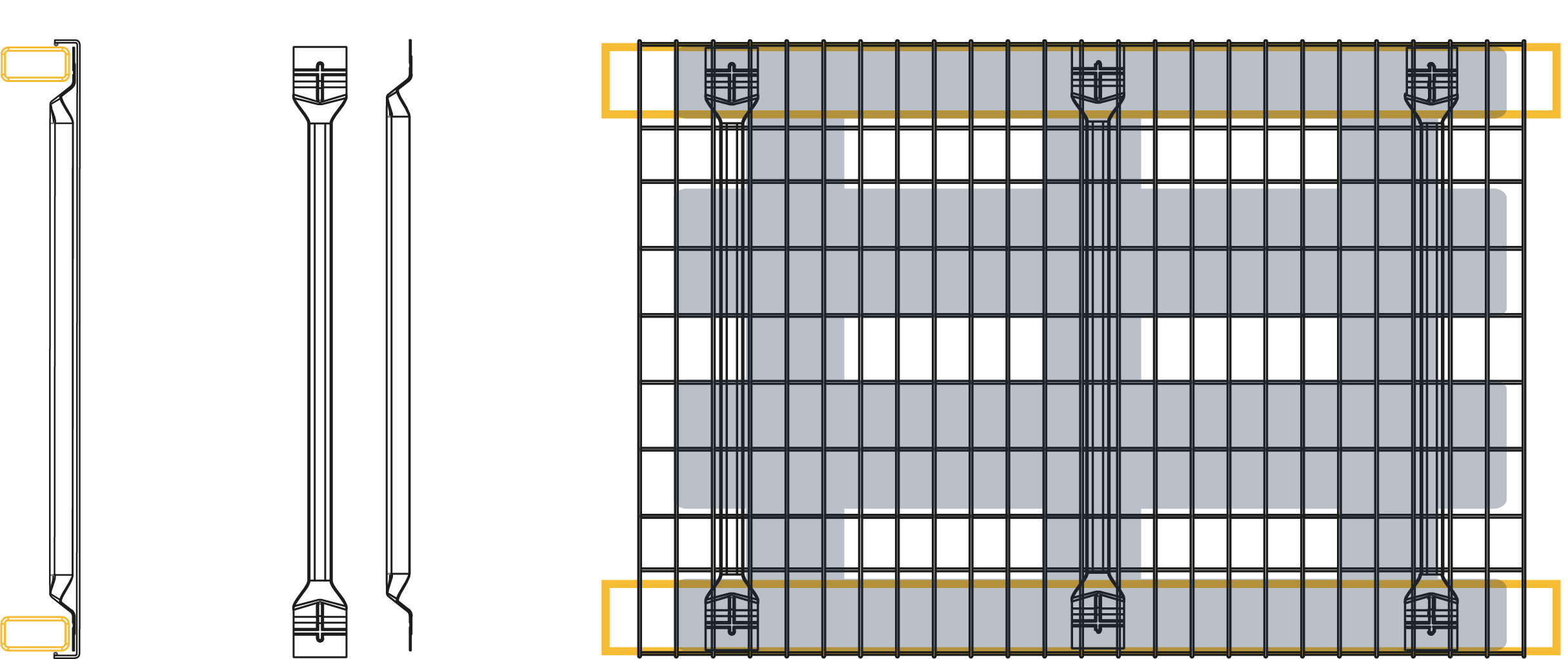

The wire mesh decks are a standard waterfall design with flared support bars to provide support. If these are not suitable for your needs, our expert sales team and experienced designers will work with you to find a more appropriate solution.

With a stock holding of 6 size variations, the powder-coated Quick Stock range can be with you in 5 – 10 working days, depending on the delivery location.

SPECIFICATION

55x100mm mesh aperture

4.6mm wire thickness

3 – 5 support bars

(depending on weight loading)

Maximum weight loading 1000kg or 1500kg

Powder coated finish

RAL7042

simple design at its finest

The design of the Quick Stock range is simple yet effective. With a waterfall overhang at the front and rear, the easySHELF™ Quick Stock decks are secured safely in place with no additional fixings for rapid and straightforward installation.

Made up of either 3 to 5 support bars, the Quick Stock decks have a maximum load capacity of 1000kgs and 1500kgs, respectively. This solution is designed for a universally distributed load that spans both beams.

The powder-coating process

Firstly, the product goes through a first stage of pre-wash and then into the wash plant where the unwanted chemicals like rust and grease are removed from the steel. The mesh then goes into a dry-off oven which heats the metal to around 160°, which allows the powder to stick better.

Now the product is prepped, it can go into the powder booth. The product itself is positively charged, and the powder is negatively charged, which makes it stick to the surface of the metal. The product then enters the curing oven. The heat bakes the powder and allows it to set.

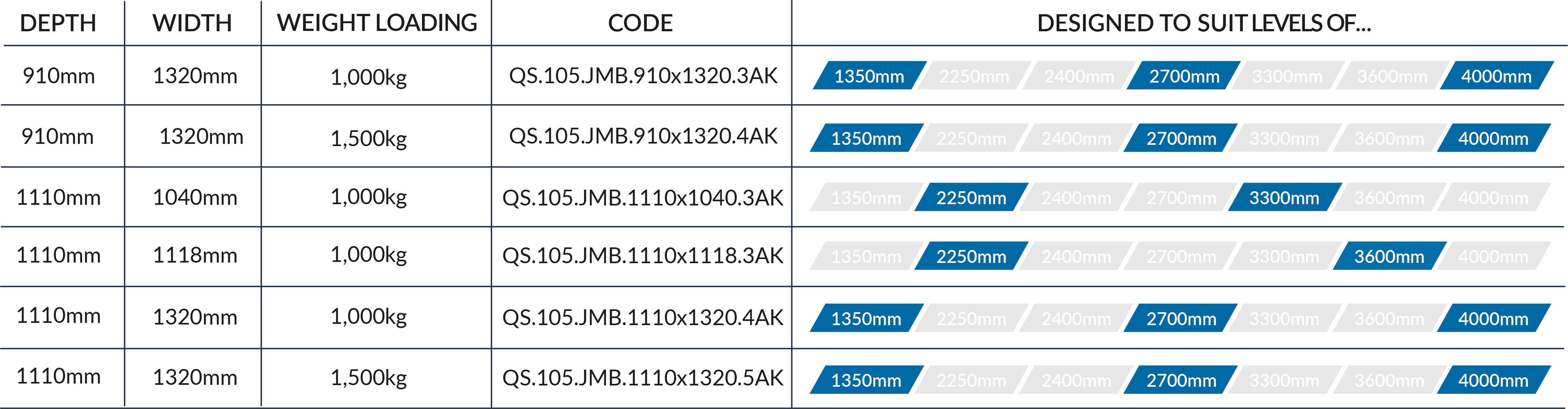

AVAILABLE SIZES

*Please note: Subject to availability. Large orders will be factored into our production plan and a lead time will be given accordingly.

*The bay will usually need to be split into multiple mesh decks. For example, a 2700mm bay will need 2x QS.105.JMB.910×1320.3Ak decks