Category:

In the world of warehouse management, maximising space while ensuring safety and improving efficiency can often seem like a challenging puzzle. However, with QTS’s fabricated warehouse shelf divider range, this challenge becomes an opportunity for innovation.

This blog post delves into the capabilities and benefits of our specialised fabricated warehouse shelf dividers, including the Hoop Divider, the Underslung Loop Divider, and the Tube Dividers, each engineered to optimise your warehouse operations.

The Fabricated easyDIVIDER range: Pallet Rack Vertical Dividers

The easyDIVIDER™ range was designed with one goal in mind: to transform traditional warehouse environments into highly efficient, safe, and optimised spaces. This is particularly crucial in industries where space utilisation directly impacts productivity and operational costs.

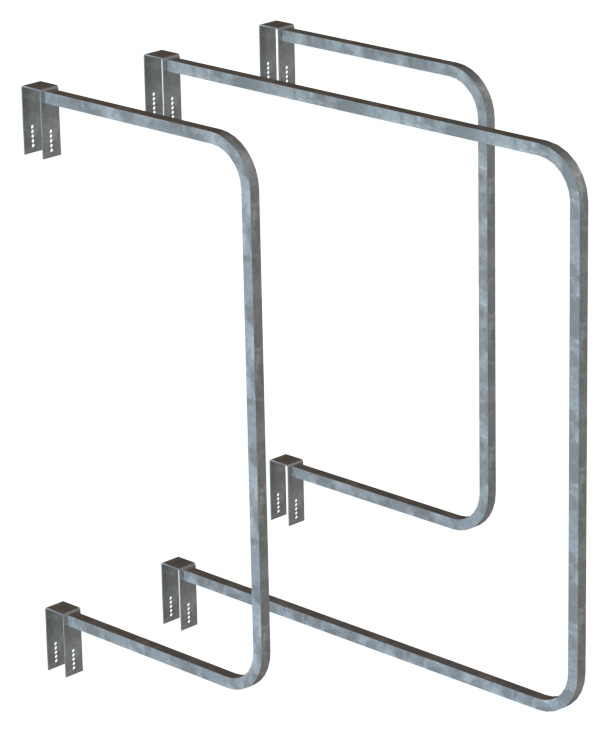

Hoop Divider For Vertical Storage Racks

Ideal for vertical storage, the Hoop Divider’s D-shaped profile is perfect for securely storing long, awkward items such as timber and piping. Its innovative design allows for easy attachment without drilling, preserving the integrity of your racking systems and ensuring a stable, reliable setup.

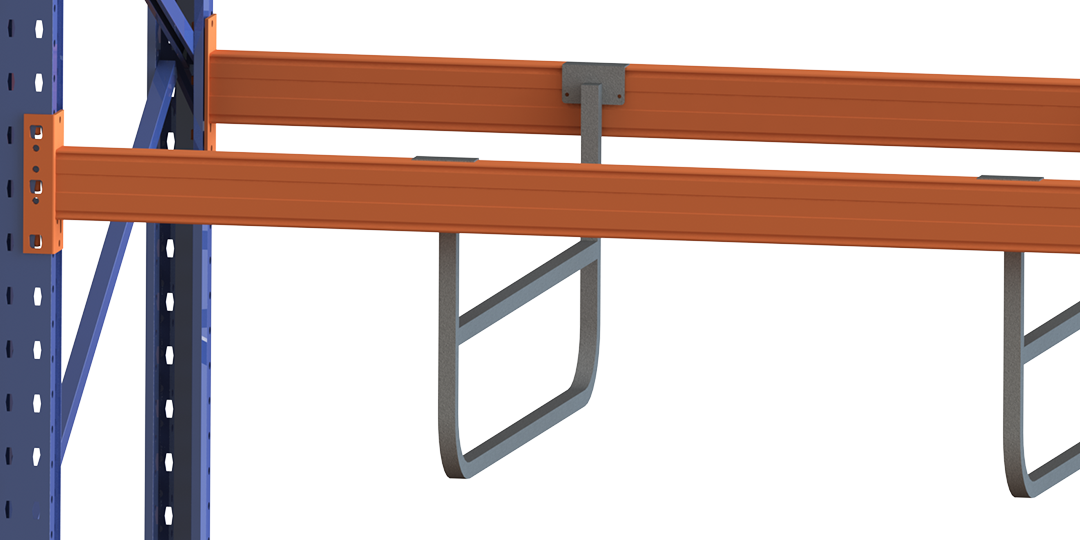

Underslung Loop Divider:

The underslung loop divider is a game-changer for storing large, flat items like sheets of wood, metal, or glass. With its robust D-shaped frame and central support bar, it provides unmatched stability and safety, preventing the bending and warping of valuable materials

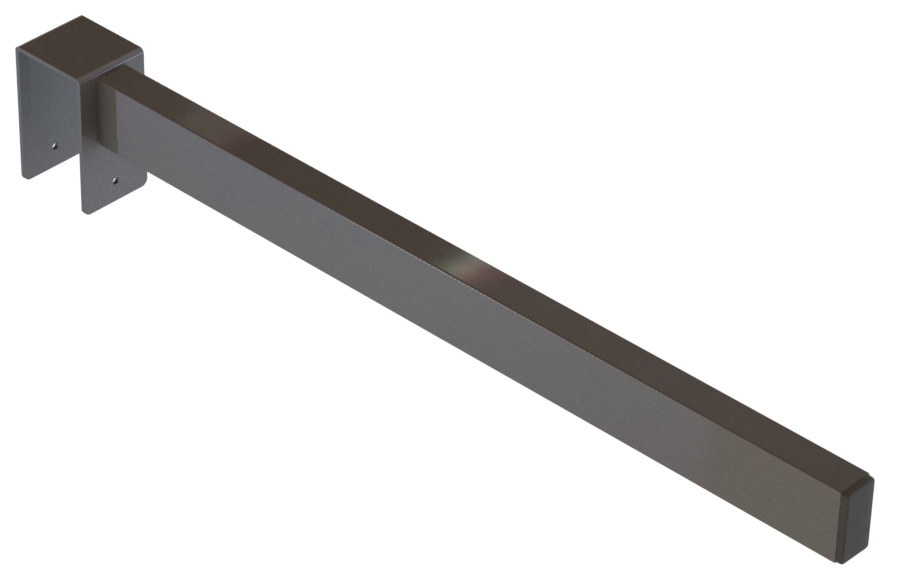

Tube Dividers For Vertical Storage Racks

The tube dividers for vertical storage racks excel in the vertical storage of slender, long items. Their versatile design and easy installation make them indispensable for efficiently organizing items like rods, pipes, and planks, ensuring quick access and systematic storage.

Potential Applications of our Warehouse Shelf Dividers

- Lumber and Timber Planks: In woodworking and building industries, long wooden planks can be stored vertically, minimising the footprint in a warehouse.

- PVC and Metal Pipes: Utilised in plumbing and other infrastructure projects, vertical storage ensures these items are organised and readily available.

- Metal Rods and Bars: Often used in construction and manufacturing, these long items can be efficiently stored vertically to save space and allow easy access.

- Window and Door Frames: Particularly in the construction and renovation sectors, vertical storage of these long and often unwieldy items facilitates easier handling and reduces the risk of damage.

- Retail Inventory: In retail or manufacturing of sporting goods, vertical storage can be an ideal way to keep items like fishing rods safely organised.

- Architectural Mouldings and Trims: Often long and slender, these decorative elements are best stored vertically to prevent damage and allow for easy sorting and retrieval.

Addressing Your Customers’s Challenges with Fabricated Warehouse Shelf Dividers

Each product in the easyDIVIDER™ range is designed to address specific storage and organisational challenges:

- Maximising Space: By facilitating vertical storage, our dividers allow for better utilisation of available space, turning previously underused areas into productive storage locations.

- Enhancing Safety: Stability and safety are paramount in warehouse settings. Our dividers secure items in place, reducing the risk of falls and other accidents, thus protecting both your workforce and your inventory.

- Increasing Operational Efficiency: With clearly defined storage areas, inventory management becomes more streamlined. This reduction in time spent locating and retrieving items can significantly speed up operations, from picking to inventory audits.

The easyDIVIDER™ Fabricated Warehouse Shelf Dividers are a must-have for storing items vertically. By enhancing space utilisation, ensuring safety, and facilitating better inventory management, these dividers help warehouses operate more efficiently which we are sure your customers will want to take advantage of.

April 2024: An ambitious restructure designed to prioritise the customer while supporting growth and expansion has been announced by Northamptonshire-based Nene Group.

As of April 2024 Warehouse Solutions, part of Nene Group, will focus solely on supplying its products and services to end-user customers.

Its trade customers will now be looked after by Qube Total Solutions (QTS), a company acquired by Nene Group in April 2021 which already specialises exclusively in supplying trade businesses, including the likes of wholesalers, distributors and manufacturers.

Thomas Pearson, CEO of the Nene Group, explained: “As a business, we believe in putting people first. This restructure is designed to ensure that we do not lose sight of this as we continue to grow. Celebrating 50 years of business this year further emphasises the importance of standing by our beliefs whilst continuing to strive for growth.”

The restructure means Nene Group’s newly formed holding (subsidiary) company NWS Group, under which Nene Warehouse Solutions, Nene Electrical, Econform and QTS (UK and Europe) sit, now has two separate and distinct lines of business and customer types: the end user, who will be serviced by Nene Warehouse Solutions, and trade businesses, who will be supported by QTS. Nene Electrical and Econform remain unchanged.

The customer has been prioritised at every stage of this restructure.

The expansion and diversification means NWS Group will now supply multiple services and products to a wide range of customers.

Thierry Schoen, Managing Director for the NWS Group, added: “This restructure is designed to simplify the customer journey and to support ambitious growth. All existing, as well as synergistic future acquisitions will sit under the NWS Group brand.”

Craig De-Lara, Managing Director of QTS, which is based in Pinxton, Nottingham, said:

“QTS’s mission remains the same – ‘to deliver exceptional supply chain solutions with passion, while fostering innovation and integrity’ – and we do this by providing all customers with the very best experience, through quality products, competitive solutions and rapid service delivery.

“QTS will continue to offer the full range of products and services that all trade customers have become accustomed to, providing a combination of engineering expertise, selection, flexibility and efficiencies, delivering real value to all trade customers in return. We have prepared and are ready for this exciting development.”

Introducing the latest addition to our rackGUARDIAN™ range: the 50mm x 100mm anti-collapse mesh panels. Tailored for businesses seeking to fortify their warehouse safety without inflating their budgets, these panels offer a pragmatic solution in the landscape of industrial safety. With a focus on affordability, durability, and ease of integration, we’ve expanded our rackGUARDIAN™ lineup to include these new panels.

Why the 50mm x 100mm Mesh Aperture Panels Matter

Warehouse safety is non-negotiable. Yet, finding solutions that balance safety, quality, and cost-efficiency is a perennial challenge for businesses. The 50mm x 100mm mesh aperture panels are designed to meet these challenges head-on, providing a robust safety feature that integrates seamlessly with existing storage systems, all the while ensuring that your budget remains intact.

The Benefits Unpacked

- Cost-Effective Solution: Leverage the economic advantages of the 50mm x 100mm mesh panels to enhance safety while managing costs.

- The Same Seamless Integration: Easily incorporate these panels into existing rackGUARDIAN™ systems for a unified safety approach.

- Improved Visibility: The 50mm x 100mm mesh design allows for better visibility, facilitating easier inventory management and safety checks.

- Same Durable Construction: Rely on the robust quality and durability that rackGUARDIAN™ is known for, now extended to our new mesh panel options

Why Choose rackGUARDIAN™?

Choosing rackGUARDIAN™ anti-collapse mesh means opting for a solution that has been rigorously tested and proven to deliver. It’s not just about the product; it’s about the peace of mind that comes with knowing you’ve invested in a solution that protects both your personnel and your inventory effectively.

Discover the difference that the new 50mm x 100mm mesh aperture panels can make in your facility. Visit our rackGUARDIAN™ product page to get started, or log in to your Quote to Site™ account and get an instant quote.

Building on the momentum from a successful debut at LogiMAT 2023, QTS GmbH is excited to announce its return to this prestigious event in Stuttgart. This year promises an even grander display with a broader spectrum of cutting-edge warehousing solutions.

LogiMAT serves as the premier international stage for intralogistics solutions and process management, making it the perfect venue for QTS GmbH to exhibit its latest advancements. Focusing on enhancing warehouse efficiency and safety, we are poised to introduce a range of innovative products that reflect our deep commitment to technological advancement and top-tier quality.

Based in Germany, QTS GmbH is rapidly gaining recognition as a key supplier in warehouse storage, safety, and security solutions. Our journey is fueled by a mission to revolutionise warehouse operations, anchored in our dedication to innovation, quality, and customer focus.

What to expect:

Our portfolio at LogiMAT 2024 will include a wide variety of products, each designed to bolster reliability, durability, and efficiency in warehouse operations. Here’s a glimpse:

easySHELF™ Wire Mesh Decking

QTS’s easySHELF™ provides a robust and adaptable solution for pallet racking in warehouses. Constructed from welded wire mesh, these decking systems enhance support for palletised goods and contribute to improved fire safety measures. They are also instrumental in streamlining inventory management.

easyDIVIDER™ Warehouse Rack Dividers

Designed to complement wire mesh decking, the easyDIVIDER™ system effectively segments warehouse storage, creating organised sections for inventory. This arrangement is particularly beneficial in environments requiring rapid and accurate order fulfillment.

easyDIVIDER™ Fabricated Dividers

The easyDIVIDER™ Fabricated series offers a versatile storage solution for bulky or elongated items like timber. This range, including various divider styles such as D-dividers and underslung dividers, is particularly favored in the building materials sector.

rackGUARDIAN™ Anti-collapse Mesh

The rackGUARDIAN™ mesh system enhances safety in warehouse storage areas. This robust addition, attachable to pallet racks, acts as a protective barrier, safeguarding both staff and products from potential accidents.

storGUARD™ Security cage and mesh partition system

The storGUARD™ offers a secure partitioning and caging solution, ideal for warehouses and factories. Its modular design of wire mesh panels and doors creates a fortified area, essential for storing sensitive or high-value items safely.

And more…

This year at LogiMAT, QTS will be releasing loads of new products. Some of these will be available on our website before the show so make sure to follow us on social media and sign up to our mailing list to stay up to date.

Visit Our Booth – 1GA28:

We invite you to join us at Stand 1GA28 in Hall 1 Gallery. Experience our innovative solutions firsthand through live demonstrations and interactive displays. Our team of experts will be on hand to discuss the efficiency and safety features of our products.

Navigating the world of business-to-business relationships goes beyond transactions; it’s about aligning with partners whose mission, vision, and core values resonate with your business objectives. At QTS, our recently updated mission and vision statements, supported by our core values, are not just internal compasses, but rather a robust framework designed to advance your business success. Let’s explore how these elements of our corporate ethos are specifically tailored to provide tangible benefits to you, our valued customers.

Our Mission

To passionately serve our customers by delivering exceptional supply chain solutions, while fostering a culture of innovation, integrity, and sustainability.

Our Mission: Serving You Passionately

We are committed to delivering exceptional supply chain solutions that don’t just meet, but exceed your expectations. This dedication is woven into our culture of innovation, integrity, and sustainability. For you, this means engaging with a partner who is continuously striving to enhance your business operations and ethics.

Our Vision

Empowering the supply chain of the future, we aim to be the industry leader in providing customer-focused, innovative, and sustainable designed and manufactured solutions, driving success for our clients and our organisation.

Our Vision: Empowering Your Future

Our vision is to empower the supply chain of the future. As we aim to be the industry leader, our focus is on providing customer-centric, innovative, and sustainably designed and manufactured solutions. This vision is about more than just leading the industry; it’s about driving success for both our clients and our organization. For you, it translates into a partnership that not only understands your current needs but is also geared towards future-proofing your operations.

Core Values: The Foundation of Our Service

- Customer First, Always: We ensure that every decision made is customer-centric.

- Solutions Experts: Our leadership in solutions benefits you through cutting-edge, efficient products.

- Value My Team: A united team means a stronger, more efficient service for you.

- Quality Delivered, No Excuse: We guarantee top-tier products and services every time.

- Transparent Culture: Honest and clear communication means you’re always in the loop.

The Benefit to You

By integrating these principles into our daily operations, we ensure a partnership that adds value to your business. Whether through innovative solutions, exceptional quality, or transparent communication, our goal is to enhance your efficiency and growth.

Last week was a monumental one for QTS as we hosted our first-ever Open Week from Monday, 23rd October to Friday, 27th October, at our facilities in Nottinghamshire. This event was curated with the aim of providing unparalleled insights into our operations and product offerings. And judging by the glowing feedback, it seems we achieved just that. If you missed out, here’s a detailed summary of what you missed.

QTS Factory Tour: Where Innovation Happens

The event kicked off with a tour of the QTS factory, led by our Head of Manufacturing, John Foster. Visitors got an exclusive behind-the-scenes look into the epicentre of innovation at QTS. It was a revelation for many, providing insight into the intricacies of our manufacturing process, from conceptualisation to the final product.

We emphasised our commitment to quality by sharing details about our ISO9001 certification and the rigorous processes that help us maintain it. The factory tour was not just about showcasing machinery and manpower; it was about spotlighting how we infuse quality into each phase of production. The tour highlighted QTS’s manufacturing capabilities and helped our customers really understand where we could assist them.

Showroom: Experience the Products

Following the factory tour, we invited our guests into our newly built showroom. Recent investments have enabled us to create a dedicated space to showcase our complete range of products, including our newly designed rackGUARDIAN™ anti-collapse mesh system.

Our visitors received an intimate look at our products in a real-world setup, allowing them to fully understand their features and benefits. The showroom visit wasn’t just a viewing experience; it was interactive. We encouraged attendees to ask questions, providing real-time answers to help them understand how each product could fit into their specific business needs.

Presentation: rackGUARDIAN™ Anti-Collapse Mesh System

After the showroom tour, we dived right into a detailed presentation on our newly designed rackGUARDIAN™ anti-collapse mesh system. From the conception of the idea to the rigorous testing phases, we revealed what went into the making of this innovative product. A highlight was the impact testing video that demonstrated the strength and resilience of the rackGUARDIAN™ system.

Quote to Site™ Demo: Revolutionising Quotations

The capstone of the Open Week was a live demonstration of our game-changing Quote to Site™ customer software. Attendees were not only shown how to navigate the system but were also given immediate access to it. The demo showcased how the portal dramatically reduces quote-generating time, thereby increasing operational efficiency.

As the event came to a close, guests were treated to a variety of food and beverages, offering a casual setting for networking and in-depth conversations. It was amazing for us to get some face-to-face time with the people whom we work so closely with week in and week out

In summary, the Open Week was a platform for learning, sharing, and growing. We are grateful to everyone who participated and made it a resounding success. If you couldn’t make it last week but would like to book a visit, contact your account manager and we would be more than happy to welcome you to the QTS facilities.

According to the estate agents Savills, warehouse storage now accounts for 566 million square feet of the UK. The last 5 years have seen the most rapid increase in unit takeup in history. The UK’s warehouse space shortage can be attributed to two main factors: the explosive growth of online shopping and the combined impact of the EU Exit and the COVID-19 pandemic. These forces have accelerated the need for transport and storage solutions, challenging businesses to find new ways to meet demand.

Why Optimising Warehouse Space is Important

Saving Money:

Effective use of warehouse space translates into savings. By optimising layout and storage methods, companies can minimize wasted space and reduce operational costs.

Increasing Productivity:

Improved storage solutions lead to a more streamlined workflow. This boosts employee productivity by enabling quicker access to items and more efficient use of space.

Strategies to Increase Warehouse Storage Capacity

Utilizing Central Ridge Decks

Central Ridge Decks provide a highly practical solution for those looking to maximize the efficiency of their storage space. By enabling loading from both sides of the pallet racking without pushing items off, it provides a stable platform to keep items separated and organized. This approach allows warehouse staff to access products easily from either side of the bay and helps in reducing product mix-ups, contributing to a smoother operational flow.

Extending Storage with Racking Extensions

The demand for increased warehouse space often leads to innovative solutions. One such method is extending storage with Racking Extensions. By extending anti-collapse mesh beyond the top of the racking, it becomes safe to utilize the top beam level, drastically increasing available space. This creative use of vertical space makes it possible to store more goods without expanding the warehouse footprint, making it a cost-effective solution.

Organising Existing Storage Levels Using easyDIVIDER™

Organisation is key in warehouse management, and tools like easyDIVIDER™ offer effective solutions. These dividers help to segment and organise storage levels, ensuring that everything is in its right place. Whether using wire pallet rack dividers or fabricated pallet rack dividers, the easyDIVIDER™ system helps to keep inventory orderly and accessible, leading to quicker fulfilment and reduced errors.

Storing Long Items Upright with Vertical Pallet Racking Dividers

Long items can be a challenge to store efficiently. Utilizing vertical pallet racking dividers provides a simple yet effective solution. By storing long items upright, more bays become available for other storage needs. This approach not only maximizes space but also makes inventory management more streamlined, ensuring that long items are easily accessible and properly protected.

The Future of the Warehousing Sector

The growth of the UK warehousing sector stands as a nationwide success story, supporting online retailers, manufacturers, and logistics companies. Research from Forrester and Savills indicates that by 2025, an additional 64 million sq ft of warehouse space will be needed for the online retail sector alone. Whilst this looks great for businesses in those industries, it is not always easy for SMEs to make large investments like renting an additional warehouse. So, making use of some of the tactics above may help to give them some breathing space to continue flourishing.

The way we approach warehouse storage is evolving. With the challenges presented by the current market landscape, innovative solutions like easySHELF™ and easyDIVIDER™ become vital in increasing storage capacity, saving costs, and enhancing efficiency.

Ready to optimise your warehouse storage? Contact QTS today and discover how our tailored solutions can transform your storage strategy.

In the competitive world of warehouse storage, every detail matters. At QTS Ltd, we’re committed to crafting superior solutions, and our inverted flared support bar for the easySHELF™ wire mesh deck is a testament to that commitment. Let’s take a closer look at why this unique design brings unbeatable advantages to your storage system.

A New Angle on Hygiene and Maintenance

Firstly, the inverted ‘U’ shape of the support bar is a simple but effective wire mesh deck solution for improved hygiene. Unlike regular flared support bars, this design prevents debris accumulation and water collection. It’s a seemingly small change that makes a world of difference, particularly in food storage environments where cleanliness is paramount. By eliminating grooves where grime and water can settle, our easySHELF™ wire mesh decks with inverted flared support bars make maintenance a breeze.

Safety First

Our team at QTS Ltd recognises that safety and efficiency go hand in hand. That’s why the hemmed edge of our inverted flared support bar is another major benefit. This thoughtful design removes sharp edges, reducing the risk of injuries to staff and damage to products. With easySHELF™, your team can work confidently, knowing that every element of your storage system prioritises safety.

Strength and Durability

The inverted flared support bar doesn’t just win points for hygiene and safety – it also offers superior strength. The distinct shape provides additional rigidity, reducing deflection in the wire mesh deck. This translates to a longer lifespan and greater weight capacity, making easySHELF™ wire mesh decks an economical choice in the long run.

With our quick stock options, making the switch to easySHELF™ is a hassle-free process. The pre-galvanised finished quick stock will now all come with our roll-formed inverted flared support bars as standard.

In an industry where efficiency, safety, and cleanliness are key, our inverted flared support bar is the game changer you need. Contact us today and take the first step towards optimising your storage system with QTS Ltd.

World Environment Day is an annual event celebrated on the 5th of June to raise awareness about environmental issues and encourage action to protect the planet. At QTS, we are committed to all of the three key areas of sustainability; economic, social and environmental. As it is World Environment Day, in this blog, we will focus on the measures we are taking towards reducing our impact on the environment.

Installation of Energy Usage Monitors on Machines by Pro-enviro:

We have partnered with Pro-enviro to install energy usage monitors on our machines. This will help us map our carbon emissions and identify areas that can be targeted for process optimization to reduce carbon emissions. This will then lead to the development of strategic documents such as the UN Sustainable Development Goals, Taking Action, and Decarbonization plans. By monitoring our energy usage, we can reduce our carbon footprint and work towards a sustainable future.

Recycling of Steel

We are committed to reducing our waste and have implemented a recycling program for steel. This ensures that our steel waste is recycled and does not end up in landfills. Steel is one of the most commonly used materials in the world, and its production has a significant environmental impact. By recycling our steel waste, we are reducing the demand for new steel production and minimizing our environmental impact. This aligns with our commitment to sustainability and our goal of reducing waste.

Recycling of Paper in the Office

We are actively working towards reducing paper waste in our office. We have implemented a paper recycling program, which ensures that our paper waste is recycled and does not end up in landfills. We have also encouraged our employees to use digital documents instead of printing, which has significantly reduced our paper usage.

Installation of Electric Car Chargers in the Car Park

It is no secret that electric vehicles have a significantly lower environmental impact than traditional petrol or diesel vehicles. With this in mind, we have installed electric car chargers in our car park to encourage our employees to switch to electric vehicles. By providing electric car chargers, we are making it easier for our employees to switch to electric vehicles and reduce their carbon footprint.

Investment in Our Leadership Team

We have invested in our leadership team to set our sustainability goals and develop clear KPIs. Our leadership team is committed to sustainability and is working towards reducing our environmental impact. By setting clear goals and KPIs, we can measure our progress and work towards a sustainable future.

LogiMAT 2023 marked the official launch of QTS GmbH supplying Wire mesh decking, wire mesh dividers, anti-collapse mesh and more into the European market…

As one of the largest international trade fairs for intralogistics and supply chain management, LogiMAT 2023 was a fantastic event to mark the formal launch of QTS GmbH. This event provided an excellent platform to showcase our latest products and solutions to the European market.

At our booth, we demonstrated our innovative solutions designed to optimize warehouse management, enhancing the productivity, efficiency, and flexibility of your space. Our team of experts were on hand to answer questions and provide demonstrations of our products, and we were thrilled to receive such positive feedback from visitors.

In addition to showcasing our products, we also had the opportunity to connect with industry professionals and learn about the latest trends and developments in the market. We were able to network with other businesses and build new partnerships, which we believe will be invaluable in the future.

Overall, our attendance at the LogiMAT 2023 exhibition was a fantastic experience, and we are already looking forward to next year’s event. We would like to thank everyone who visited our booth and helped to make this such a successful event. See you at LogiMAT 2024!

Craig De-Lara, Managing Director for QTS, had this to say:

“LogiMAT is an extremely impressive exhibition for our target market and this year was no different; however, I’m pleased the QTS team and I got to experience the show first-hand!!

As we extend our products and services into Europe with the birth of QTS GmbH and new team members, I look back and I would describe our experience as an extremely welcoming, positive and exciting one.

Our focus is now shifted to looking ahead and building on those newfound relationships.

We certainly look forward to attending LogiMAT 2024 and seeing how our European arm grows.”