Understanding load layouts for wire decking

An element of warehouse design often overlooked is the load layout the customer will require. Choosing a suitable mesh deck for the load layout will ensure that the warehouse remains safe for your staff and the storage of products.

Contents

What do we mean by load layout and capacity?

When planning your new warehouse space, knowledge and understanding of the items being stored are vital. All the top health & safety organisations like SEMA will expect to have the weight loading capacities detailed on load notices at the end of each run of racking. The main things needed for consideration are:

- The size and shape of the goods

- Products are palletised or not

- Weight of the goods

- If goods will be stored spanning or in between the beams

A combination of these factors will dictate the load layout and the features required of a mesh deck to provide suitable and safe storage. So, let’s get onto some of the different load layouts you may encounter…

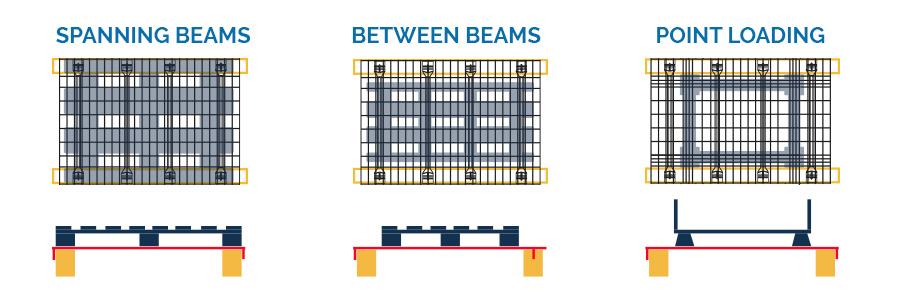

Spanning the beams:

The most common load layout is for the pallet to span both beams. You may be thinking, “Why do I need a mesh deck if the weight is held by the beams of the racking system?”. The simple answer is safety. Far too often, accidents occur because of the accuracy required to load the pallet across beams that may only be 50mm wide. Having a wire mesh deck in place reduces the risk of accidents and is also an extra level of support in case the pallet is damaged or breaks.

From a specification point of view, this load layout will mean the deck doesn’t need to hold all the weight all the time. Therefore a thinner wire and tinner support bar material is used, reducing the cost of the deck while still providing the support you need.

Between the beams:

A between-the-beams load layout typically occurs when the customer wants to use smaller pallets than the depth of their existing pallet tracking system. We often see this when the usage of the racking has changed, but the customer does not want to change their racking system as this can be expensive. Instead, they require a mesh deck that suits their racking but can hold the weight of the pallet in between the beams.

Ensuring the mesh deck is capable of the weight, there are a few specification changes we make. Firstly, we will increase the thickness of our support bars making the deck significantly stronger and reducing deflection. Secondly, we may also increase the diameter of the wire mesh to provide additional support if needed.

Point loading:

Point loading of a mesh deck occurs when the goods have not been palletised or the weight has not been uniformly distributed over the deck. For example, if you are storing goods on individual boxes or using a stillage pallet. This method puts an unnecessarily large amount of pressure on a few wires causing the welds to snap or the mesh to deflect past acceptable standards.

To adapt the easySHELF™ to this load layout, there are a few potential changes we can make. Firstly, we can use a thicker wire in a different aperture configuration which will spread the load across multiple wires and weld, providing additional strength in this area only. The other option is to add baffle plates to the deck. These solid metal plates spread the weight and can handle uneven points of pressure.

As the UK’s leading wire mesh manufacturer who better to trust with the technical elements of your project? Please get in touch below if you would like more information on load layouts or would like us to quote you for a job. Alternatively, head to our resource centre where you will find all our product brochures, such as the easySHELF™ wire mesh deck range, available for download.

Share This: