Wire mesh decking – One size does not fit all

If you have been in the industry for a long time, you probably already have a good idea about what wire mesh decking solution you need for any given environment. However, for those of you that are relatively new to the industry, or if you require a bit of a refresher, this blog will cover some of the key points of wire mesh deck selections.

Contents

Choosing the right wire mesh decking for your beam type:

Before considering which wire mesh deck you require, you need to identify the type of beam your racking or shelving has. The most common type is the box beam which is used when storing large, heavy or palletised products on pallet racking, and also storing smaller products on long-span shelving. There are multiple choices of wire mesh decking available, all depending on the beam types.

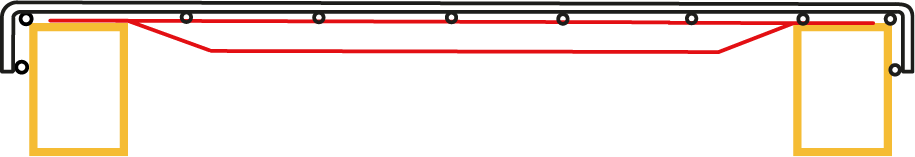

Box beam:

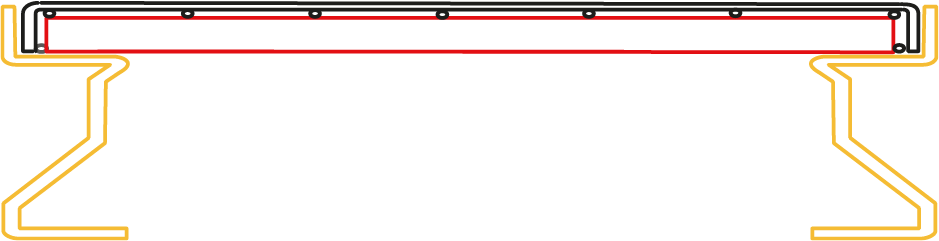

Z-step beam:

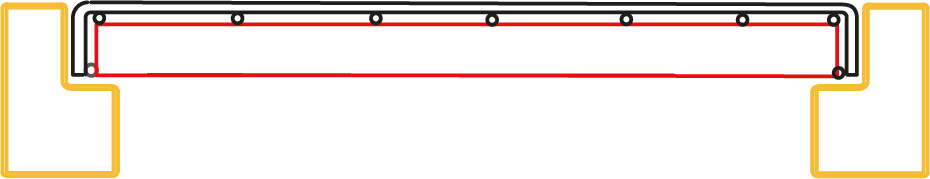

Box step beam:

A box beam is a common solution for most warehouses. This would require a standard mesh deck.

Most commonly seen beam for long-span racking in e-commerce warehouses. Requires a step deck solution.

A different style of step beam that still requires a step-deck solution.

Racking depth and the width of the bay:

To correctly size your wire mesh deck, we will need to know how deep and how wide each bay is. We will then need to know the width of the bays. The racking bay will likely be bigger than our standard mesh decks. Therefore, you will have multiple decks per bay. Contact us and let us know the bay size, and we will work out the most economical solution.

Box beam:

Measure the outer edge to the outer edge as your wire mesh deck will have waterfall edges that sit over the edge of the beam.

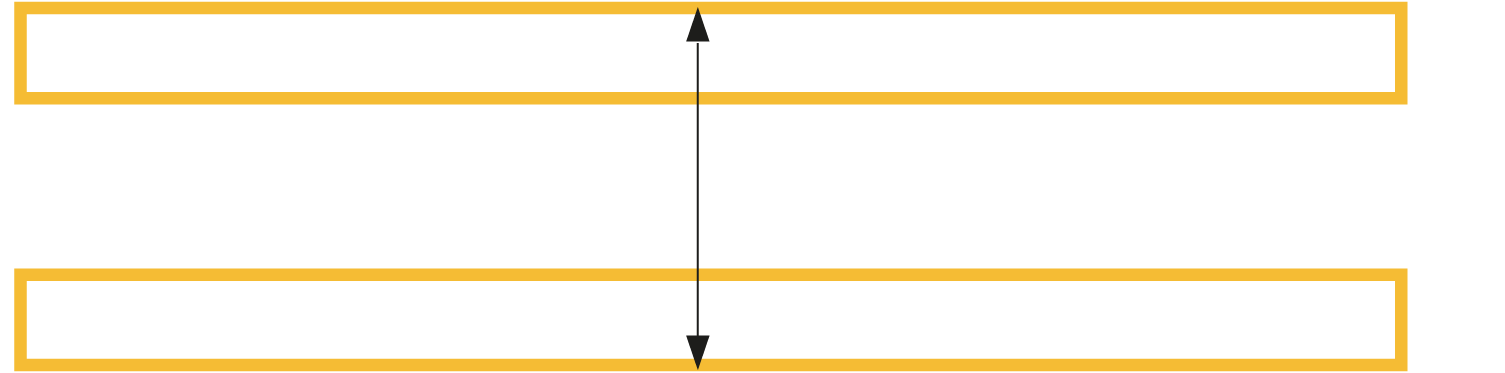

Step beam:

Measure from the back of the step to the back of the other step as your step deck will sit in the step, level with the top of the step.

Load layouts and weight loading:

The amount of weight that each deck needs to hold and the way the deck will be loaded will affect what specifications we suggest. Whilst we would rarely alter the overall dimensions of the wire mesh decking, the load layout and weight loading will determine how many support bars you need, what thickness of support bar and how thick the wire is. Weight loading and layouts can be challenging to get your head around. So, we have written a blog about weight loading to further assist you in wire mesh decking selection.

Choosing an appropriate finish for the environment.

Lastly, you need to consider the environment the wire mesh decking is in – is it inside a warehouse, outside in the rain or maybe in an industrial fridge or freezer? These are important factors as they will dictate the type of finish you will need. For inside a warehouse, our standard galvanized wire decking would be the most appropriate solution. However, in cold or damp conditions, galvanised wire decking would not be appropriate. In this case, QTS would offer a hot-dipped galvanized solution to protect your wire decking from moisture.

As always, if you have any questions about the content of this blog or would like to enquire, please email your account manager, or fill in the form below.

Share This: