Cold storage facilities; How QTS can help you with your next cold storage warehouse…

Cold storage facilities are an essential link in the global supply chain. Cold storage is a vital aspect of storage for many businesses because they help to keep their goods fresh and safe for longer. However, not all cold storage warehouses are equal. A good cold storage warehouse will be clean and well-maintained. This blog will look at some fundamental aspects of a cold storage warehouse to help you provide your customers with the perfect setup for success.

Contents

Why are cold storage warehouses important?

Cold storage is crucial in some industries because of the perishable nature of their goods. A lower temperature prevents bacteria from growing. One of the most common examples of this is the storage of food. The cold storage of food is one of the most highly regulated sectors of the warehousing industry. In the UK, such warehouses are subject to checks from the Food Standards Agency (FSA). The incorrect storage of organic matter accelerates the reproduction of any bacteria that may be present as they have a source of energy to reproduce. Another example is the storage of chemicals that can become more reactive at higher temperatures. With either example, there is a risk of causing harm to consumers and loss of stock, neither of which any successful company want to happen.

So how can you ensure that a warehouse is set up correctly for this type of use?

Wire mesh deck design:

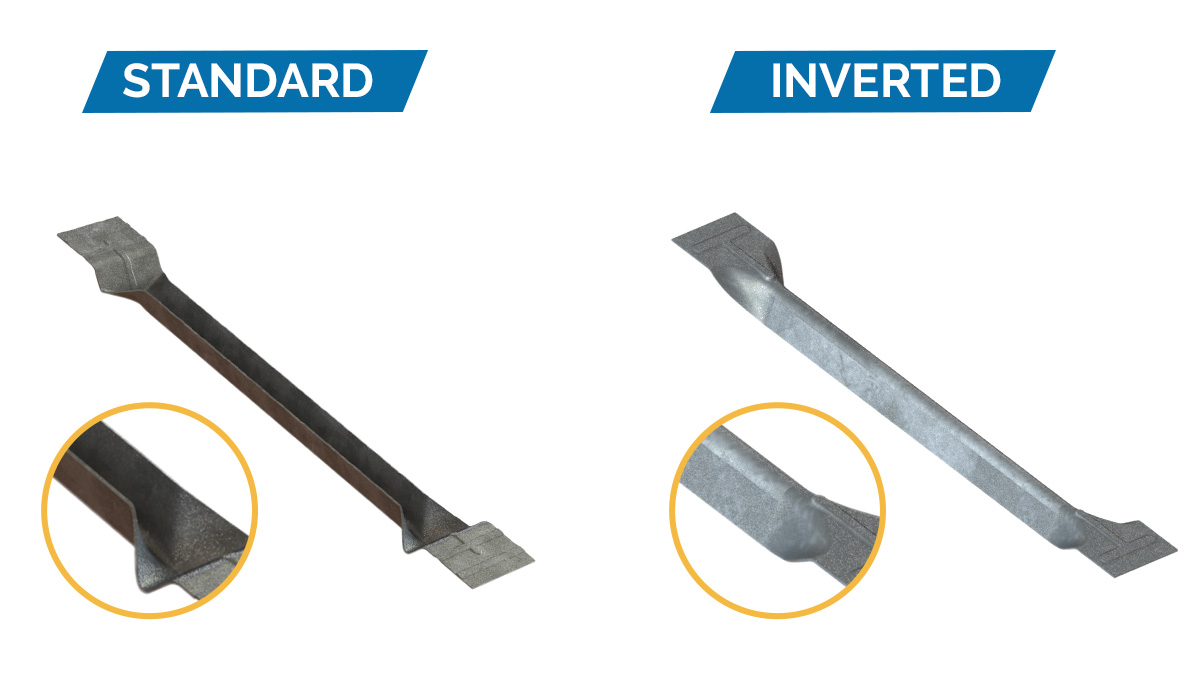

In a cold storage environment, there is usually an emphasis on hygiene, which will involve the regular sanitisation of racking and incumbent mesh decks. Commonly, wire mesh decks are supplied with support bars that are either flared or c-channel. These bars have an open groove which means that food, dust or water will gather in these gaps, which means they will require a lot of work to ensure they meet standards. At QTS, it is easy to change the design of your support bar and would recommend using our inverted flared support bar. This Bar means there is no gap for anything to gather, and its shape means that water will run off more easily.

Choose the right finish:

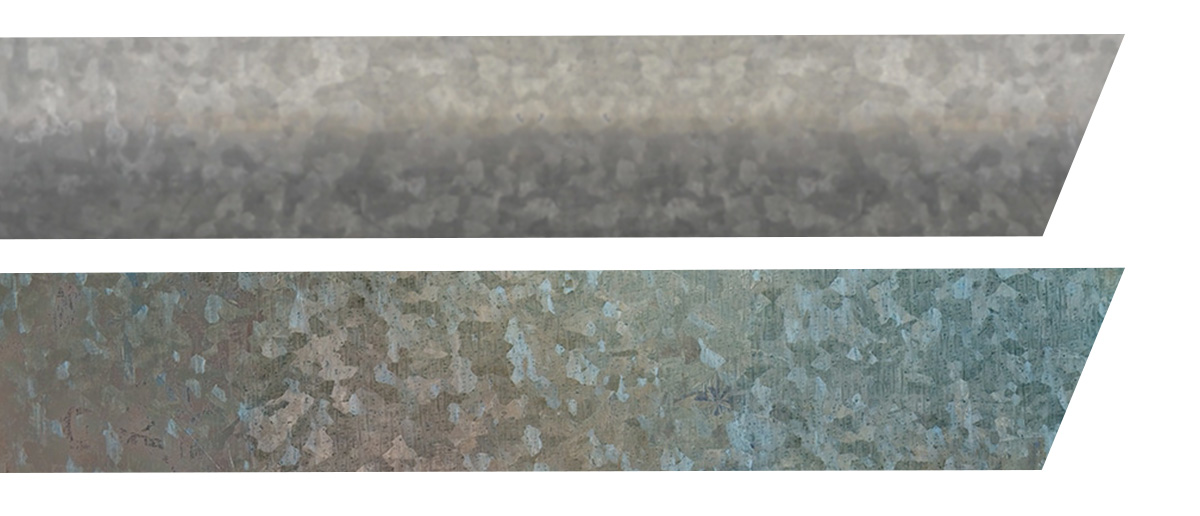

The second element that can be changed on the QTS mesh decking is the finish. The standard stock deck finish is pre-galvanised, which is suitable for the cold environment. However, QTS also offer a hot-dipped galvanised option which is longer lasting in cold environments and will cope with regular exposure to moisture during cleaning.

Create efficient picking locations for easy inventory management:

Food items are often stored in boxes or smaller packages that look very similar and could cause confusion for warehouse operatives. Firstly, it is imperative that everything is labelled correctly. This will make it easy to identify boxes and ensure food is not stored incorrectly. For example, it is standard practice to store meat on the lower levels of the racking system so as not to contaminate other foods. Another way QTS can help keep your warehouse organised is by adding easyDIVIDERS™ wire mesh dividers to your decks. These will compartmentalise the bay, creating a pick location that will stop accidental cross-contamination of foods.

We can help you find the right solution for your business needs by providing expert advice on everything from design through to additions to make your customer’s warehouse compliant, safe and efficient. Fill in the form below to talk to one of our expert sales team.

Share This: