Latest News

Trade Division Merges Into QTS…

Our recent press release contains some very important and exciting news. Please ensure you read the below for more information.

The Experts in Mesh

The leading welded wire mesh manufacturer in the UK

QTS Ltd is the leading UK manufacturer of wire weld mesh solutions for warehouse spaces. From warehouse storage to safety and security, QTS have you covered. Our approach is simple: we combine innovative design with high-grade materials; made in UK and EU steel mills; to create a quality product for our customers. A combination of an experienced sales team, complete with in-house designers and a knowledgeable manufacturing team, have all contributed to us becoming the top UK wire mesh manufacturers. QTS are always on hand to create a warehouse storage solution tailored to your needs.

easySHELF™

Wire Decking

The easySHELF™ is a low-weight, high-strength wire mesh deck system. This is suitable for storing palletised goods or single units safely.

- Improved Light Levels

- Easy to Install

- Improved Fire Safety

- Tested & Certified

easyDIVIDER™

Warehouse Rack Dividers

The easyDIVIDER™ warehouse racking shelf dividers are used to separate the pallet racking bay. This creates smaller shelf locations ideal for warehouse picking and for keeping an organised warehouse.

- Suitable for all needs

- Fast and easy to attach with the pre-welded clips

- Designed for strength and rigidity

- Available in a variety of depths & heights

easyBAR™

Pallet racking support bars

The easyBAR™ pallet support bars are a great way to add additional support to your racking system. This elevates the risk of improper loading or broken pallets.

- Provides additional support

- The most cost-effective solution

- Made from top quality sourced

- The c-cups simply sit over the beam tops

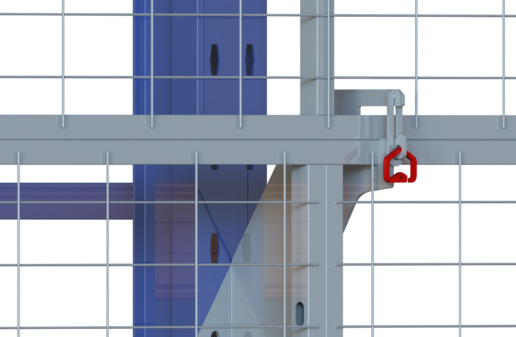

rackGUARDIAN™

Anti-collapse mesh

The rackGUARDIAN™ anti-collapse mesh range is made up of framed wire mesh panels that are attached to the back of the racking system to prevent pallets or items from falling off the racking.

- Creates a physical barrier

- Modular panelled system

- QTS stock panel sizes match most racking bay sizes

- U-capping can be purchased alongside our panels

storGUARD™

Wire mesh security cage and mesh partition system

The storGUARD™ system is a modular product comprised of posts, framed wire mesh panels and clips designed to create mesh partition walls and warehouse security cage systems that allow you to restrict access.

- Designed for strength

- Easily configured for your warehouse

- Fast and easy to install without any hassle

- Suitable for all applications, budgets and security needs

Our Services

Our tailored services address all our customer’s needs

Project Management

A hands-on approach to managing our large or obscure projects to ensure they run as smoothly as possible.

Design Services

Can’t find a wire mesh solution to suit your needs? Let QTS design you a bespoke solution.

Download our Brochures

Download a digital copy of our wide range of brochures. Alternatively, fill in form to receive a physical copy.

We always specify QTS due to the quality and the customers love the easySHELF.

Chris, Hertfordshire

The company wanted to go wire mesh decks rather than timber, as they felt it was better for their company needs. we are very happy with the project and the finish.

A satisfied Customer about our wire mesh deck range

Service is excellent, always helpful and very quick to reply

A long standing trade customer

Our Vision

Our approach to manufacturing is simple…

We ensure that our products are made from quality materials, using the latest technology and equipment, combined with highly skilled employees, to achieve the highest standards for you.

Our News

The latest updates from our blog